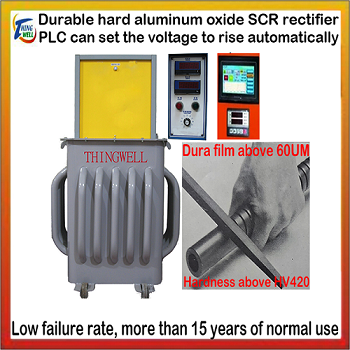

Electroplating rectifier, salt spray testing machine, constant temperature and humidity testing machine, composite salt spray testing machine, PVC dipping equipment, aquaculture related equipment, titanium heater, other products, etc... - Aluminum oxide hard treatment, durable oil-immersed water-cooled SCR electroplating rectifier

Model Name.:Aluminum oxide hard treatment, durable oil-immersed water-cooled SCR electroplating rectifier

- Model No.:DC:0~60V/0~1,000A/0~1,500A/0~2,000A/0~3,000A.

- Application: The surface treatment hard film of various aluminum alloy parts, the film thickness reaches 20~60UM, the hardness reaches 200~450HV, can wear resistance, corrosion resistance, insulation, voltage resistance, etc...

- Patent Region:not

Product Feature:

OEM produces and provides various goods and services to customers.

1. Ourcompany has been a manufacturer, trader and providing customers with variousproducts and services for more than 30 years.

2. Ourcompanys product professional advantage areas: machinery, experimentalmachines, electromechanical, chemistry, painting, materials and OEM processing of metal and non-metal material parts,etc... Buyers dont have to worry about quality issues.

Comparison of advantages and disadvantagesof aluminum anodized hard film rectifier (high frequency water cooling and SCRoil immersion water cooling)

Specification: DC:0~60V/0~1,000A/0~1,500A/0~2,000A/0~3,000A. (DC: voltage and ampere can bespecified for specifications).PLC can set the voltage to rise automatically.

AC: 220/380/415/440V three-phase.

Various aluminum alloy anodic oxidation hard treatment, hard film up to 20~60UM, hardness up to HV250~450.

SCR machine description:

1. Oil-immersed water-cooled SCR machine Advantages: the fault is very low, the maintenance is easy, and the electromechanical technician can repair it, average normal use for more than 15 years.

2. Disadvantages: The machine is heavy, large in size, and more expensive than high-frequency price machines.

3. The anodized hard film treatment time of most workpieces is very long, and the machine cannot be stopped arbitrarily after starting the machine.

4. Taiwan Sanchong Heji Co., Ltd. He is the first professional aluminum alloy anode hard film processing factory in Taiwan. The SCR machine has a life of 16 years.

5.Taiwan aluminum alloy anode hard film treatment machine is the main choice in this picture.

6.Quality A/B/C/ grade, different prices and durability. The weight and size of C/ grade are about 2/5 smaller than A/B grade.

High frequency machine description:

1. Advantages: It saves electricity than SCR machine, the machine is light, small in size, and the price is cheaper than SCR.

2. Disadvantages: Parts are easily corroded by acid and alkali gas, high failure rate, not durable, Buying high-frequency machine failures, ordinary electromechanical technicians cannot repair it, and must be repaired by the factory that produces high-frequency machines.

3. When the road is far away, in addition to affecting production, the maintenance date is very long and transportation-related costs are also high.

4. DC: Above 0-60V 0-1,000A High frequency water-cooled electroplating rectifier (See picture) can use multiple set in parallel, although one set of the failures will not significantly affect the use, but the power is reduced, production is also reduced. And the faulty set still needs to be repaired by the manufacturer. (DC: voltage and ampere can bespecified for specifications).

5. Quality A/B/C grade, different prices and durability.

Note: If the machine must be cooled with water, there must be no shortage of water, the water quality must be clean, and there must be no impurities. When the water quality contains iron ions, calcium ions, and fine sand, the machine is prone to failure.

Any product has different quality and different price, for your reference.

Taiwan Right Way stock listed company, aluminum alloy anode hard film treatment equipment and technology are all completed by our company.

If your company needs the transfer of aluminum alloy anodic oxidation hard film treatment technology, our company can provide 20 years of technical staff guidance.

●ThingWell Enterprise Co., Ltd. reserves the right to modify appearance, specification, material without notice in advance, all above mentioned information are just for reference only

QuickMenu

- Electroplating rectifier, salt spray testing machine, constant temperature and humidity testing machine, composite salt spray testing machine, PVC dipping equipment, aquaculture related equipment, titanium heater, other products, etc...

- PLA, PBAT, PHAs, PBS, composite modified particles with different components, and plant fiber composite particles can be fully biodegraded and meet 100% environmental requirements.

- COPA COPES TPU EVA hot melt adhesive granules/powder, various masterbatches, LED PP PC light diffusion masterbatch, PMMA powder, manicure supplies, etc...

- Aquaculture related equipment and supplies, IoT intelligent control, titanium submersible heater, ornamental fish quartz titanium heater, aerator, fish pond filter, chlorine dioxide sterilizing tablets, feed additives, etc...

- Medical-grade non-PVC infusion film (for blown film and injection molding PVC infusion film granules, PP granules for infusion bottles, TPE infusion film granules), medical-grade food-grade packaging materials, etc...

1F,No.14,Ln.661,Sec.5,Chungsin Rd.,Sanchong Dist.,New Taipei City 241, Taiwan.

TEL:886-2-2995-2954 FAX:886-2-2995-7615

China Factory: Shajiao Industrial Zone, Humen Town, Dongguan City 523936 , Guangdong Province.(Sand Near Kok Hospital).