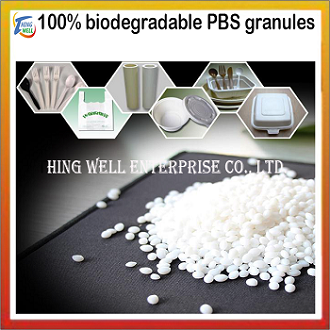

PLA, PBAT, PHAs, PBS, composite modified particles with different components, and plant fiber composite particles can be fully biodegraded and meet 100% environmental requirements. - Supply PBS 100%fully biodegradable granules

Model Name.:Supply PBS 100%fully biodegradable granules

- Model No.:

- Application: Application areas: injection molding, tableware, blown film, blow molding, blister molding, spinning, fishing nets, engineering accessories, medical and other related product use fields.

- Patent Region:not

Product Feature:

OEM produces and provides various goods and services to customers.

1. Ourcompany has been a manufacturer, trader and providing customers with variousproducts and services for more than 30 years.

2. Ourcompanys product professional advantage areas: machinery, experimentalmachines, electromechanical, chemistry, painting, materials and OEM processing of metal and non-metal material parts,etc... Buyers dont have to worry about quality issues.

Supply PBS 100%fully biodegradable granules

The cost of common grade unmodified composite biodegradable particles on the market is as follows: | |

PBAT | $ |

PLA | $$ |

PBS | $$$ |

PHA | $$$$ |

Different brands, different qualities, different uses, different quantities, different prices, the above are for reference only. | |

Introduction to PBS:

Color:natural white.

1. PBS (polybutylene succinate)is formed by the condensation polymerization of succinic acid and butyleneglycol. The resin is milky white, odorless and tasteless, and is easilydecomposed and metabolized by enzymes in various microorganisms, animals andplants in nature. It eventually decomposes into carbon dioxide and water and isa typical completely biodegradable polymer material. BioPBS™ plastic pelletsare produced by fermentation of biological resources.

2. PBS processing studies. Research on processing technology of PBS series materials (including resin and its modified products) and preparation of products. The existing general polyolefin processing equipment was used to carry out research on PBS molding processing technology and the development of related products.3. Currently, according to differences in processing environment and temperature, biodegradable certification types are roughly divided into (Industrial Composting) (Home Composting) (SoilBiodegradable), (Water Biodegradable) (Marine Biodegradable), etc..

4. Overall, the ease of biological decomposition depends on the environment, temperature, bacterial species type and concentration. From the perspective of microbial flora, the flora in soil is the most abundant, including fungi, bacteria, actinomycetes, etc, while freshwater and seawater environments are dominated by bacteria. In addition, there are specifications for specific application products of biodegradable (Mulch Film).

5.Unmodified composite particle products: Average temperature resistance is about 80-85℃. (PBS modified composite particles can withstand a temperature of over 100℃)

6.Application areas: injection molding, tableware, spinning, fishing nets, engineering accessories, medical, blow molding, blister molding, blown film, etc... fields.

7.Warm reminder: PBS particles are used in blow molding, injection molding, extrusion, film blowing, blister molding, sheets, etc. Any product has different ingredients, different qualities, different needs and different prices. To ensure it meets the buyers needs, please inform the purpose.

8.Storage: The temperature during transportation and storage should not exceed 70°C, and the resin should be stored in a dry and ventilated warehouse to prevent moisture. Avoid contact with soil, water and sludge, direct sunlight and extreme temperatures. The maximum shelf life is 1 years when packaged in sealed conditions at an ambient temperature of 23°C.

●ThingWell Enterprise Co., Ltd. reserves the rightto modify appearance, specification, material without notice in advance, all above mentionedinformation are just for reference only

QuickMenu

- Electroplating rectifier, salt spray testing machine, constant temperature and humidity testing machine, composite salt spray testing machine, PVC dipping equipment, aquaculture related equipment, titanium heater, other products, etc...

- PLA, PBAT, PHAs, PBS, composite modified particles with different components, and plant fiber composite particles can be fully biodegraded and meet 100% environmental requirements.

- COPA COPES TPU EVA hot melt adhesive granules/powder, various masterbatches, LED PP PC light diffusion masterbatch, PMMA powder, manicure supplies, etc...

- Aquaculture related equipment and supplies, IoT intelligent control, titanium submersible heater, ornamental fish quartz titanium heater, aerator, fish pond filter, chlorine dioxide sterilizing tablets, feed additives, etc...

- Medical-grade non-PVC infusion film (for blown film and injection molding PVC infusion film granules, PP granules for infusion bottles, TPE infusion film granules), medical-grade food-grade packaging materials, etc...

1F,No.14,Ln.661,Sec.5,Chungsin Rd.,Sanchong Dist.,New Taipei City 241, Taiwan.

TEL:886-2-2995-2954 FAX:886-2-2995-7615

China Factory: Shajiao Industrial Zone, Humen Town, Dongguan City 523936 , Guangdong Province.(Sand Near Kok Hospital).